Our Technology

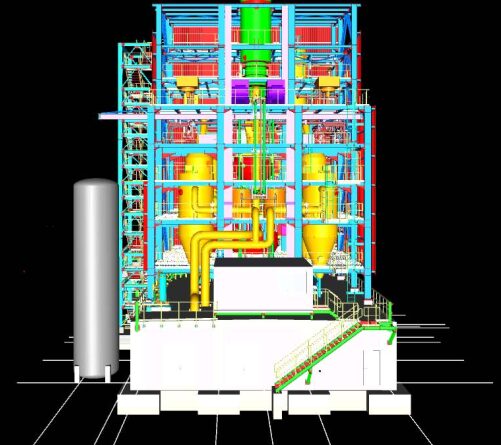

Syn X Energy's gasification process exposes waste to a temperature in excess of 1650°C to produce clean, high quality synthesis gas (Syngas).

Our technology captures all CO2 from the process and the remaining slag is used for industrial purposes.

Once running our gasification plants are self-powering, using its own Syngas from waste to power the plant turbine and remaining independent from the electricity grid.

Unique

Syn X Energy's unique gasification technology delivers an environmentally friendly and commercially viable alternative to large landfills and their emitted pollutants, such as methane and leachate.

Our High Temperature Gasification of Waste (HTGW) technology can provide a reliable, sustainable supply of Synthesis Gas (SYNGAS) that can be processed and refined into Sustainable Aviation Fuel, Hydrogen, Renewable Fuels, Electricity, Ammonia, and Methanol at competitive market rates.

Syn X Energy's gasification process exposes waste to such high temperatures that it is gasified and DOES NOT burn the waste like incineration does.

Syn X Energy gasification technology uses a renewable source and is a near-zero or sometimes carbon-negative process. Waste has been identified as a "renewable" source as it is a continuous product of living in the 21st century. Waste will always be available and will be required to be processed.

Proven

After more than 20 years of testing, development and continued enhancement of the technology we have proven, commercially-ready and viable technology with the highest energy capture efficiency in the market.

Best In Class

Designed with the help and input of multi-discipline Engineering and Plant Construction experts, our proven technology operates at the highest energy capture rates of any gasification technology in the world.

Our independently verified energy capture rates are 50% higher than the nearest market competitor.

Experience

We have decades of extensive experience in biomass/thermal projects and other leading-edge technologies.

We design and supply advanced HTGW Gasification Plants that are scalable to suit the client's needs and waste inputs.

- Inherently Clean and Reliable

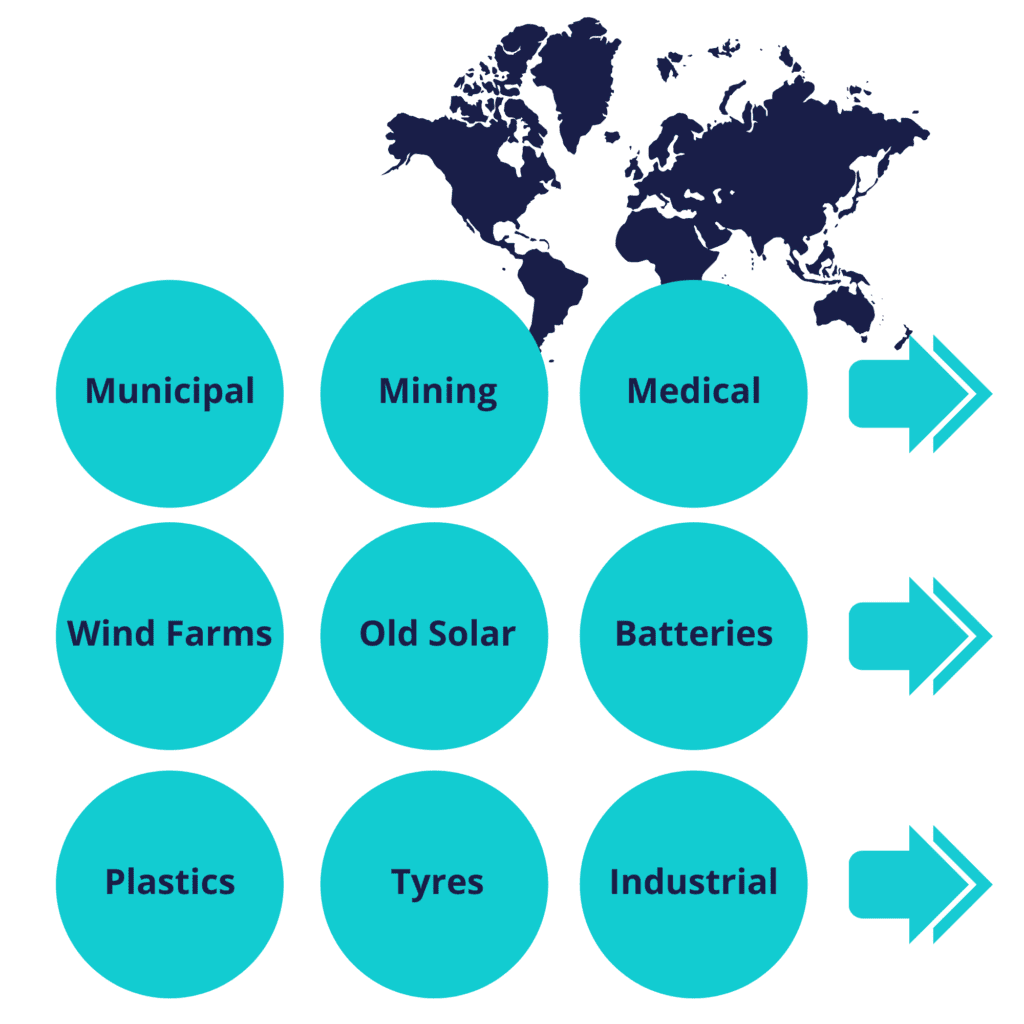

- Processes almost all waste feedstocks

- Scalable from 100tpd to multiple 3,000tpd large industrial plants

- Very low in emissions and no ash residue; negligible dusts and salts

- Economically integrated into existing structures

View a more indepth table to understand the differences between Gasification of Waste versus Incineration of Waste and why Gasification is a far superior technology.

Our Waste-to-X Process

Feedstock Sources

Discover What Is Possible And How We Make A Difference With Your Country's Solid Waste...